Marples 24 Tooth Rip blade

Irwin’s latest entry into the bargain blade segment: Marples 24 Tooth Rip blade

Table saw blades are ever evolving and getting better. Additionally home-based woodworking hobbyists are always on the hunt for the next best thing that will not break the bank. Irwin has put major focus into the rough construction/framing industry since the departure of their Woodworking series blades. They have re-entered the game recently with the Marples series of blades. The Marples is claimed to be a complete departure from their current Marathon line-up. They are made in a brand new facility in Italy. I wanted to see how this ripping blade stood up to its direct competition - the tried and true Freud Diablo.

Brand new in the package I have a 24 tooth Diablo rip blade, and a 24 tooth Irwin Marples rip blade.

Note: This review is for the Irwin Marples blade that that will be the focus. The Freud Diablo was used for comparison as it is widely recognized and used; and is in the same price point. All cuts were performed on a perfectly tuned Ridgid R4512 using a zero clearance throat plate.

First impressions

After handling both blades out of the packaging, the Irwin felt heavier. Sure enough, it weighs half an ounce more:

Irwin at an even 24 oz

Freud Diablo at 23.5 oz

Irwin is really touting how much carbide their blades have. The difference between these two is very apparent, and that is probably where that .5oz weight difference comes from:

Use

Freud Diablo:

First up was the Diablo. I made a new cutting board and ripped some 5/4 (actual thickness at the table saw was 1 1/8”) cherry, hard maple, and walnut.

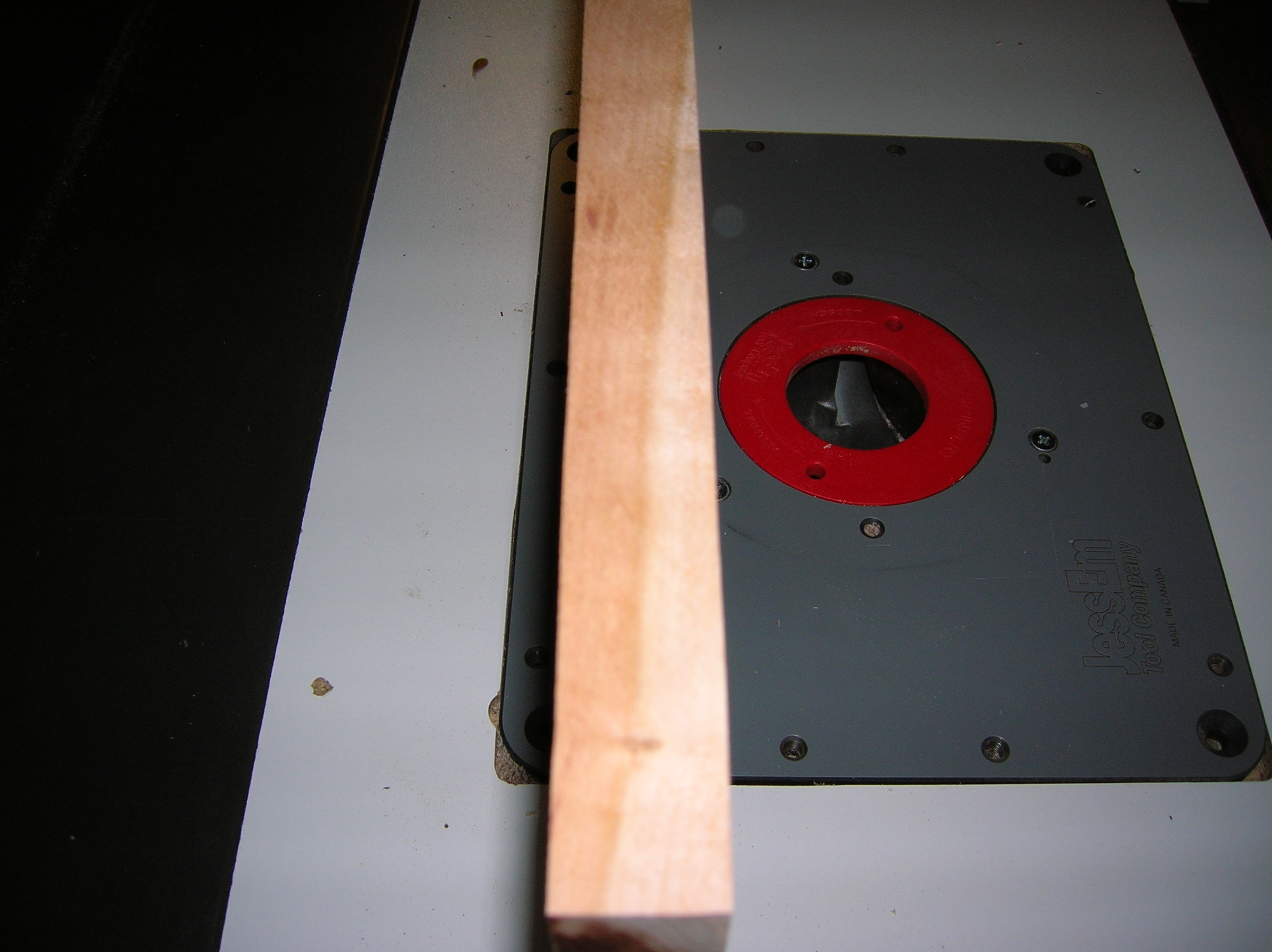

After getting everything lined up, the cherry went through the saw first. I could feed the stock quickly and there was not much complaining from the saw. The cut in the cherry was pretty clean. It’s tough to tell from the picture, but this will need to be sanded before it gets any glue:

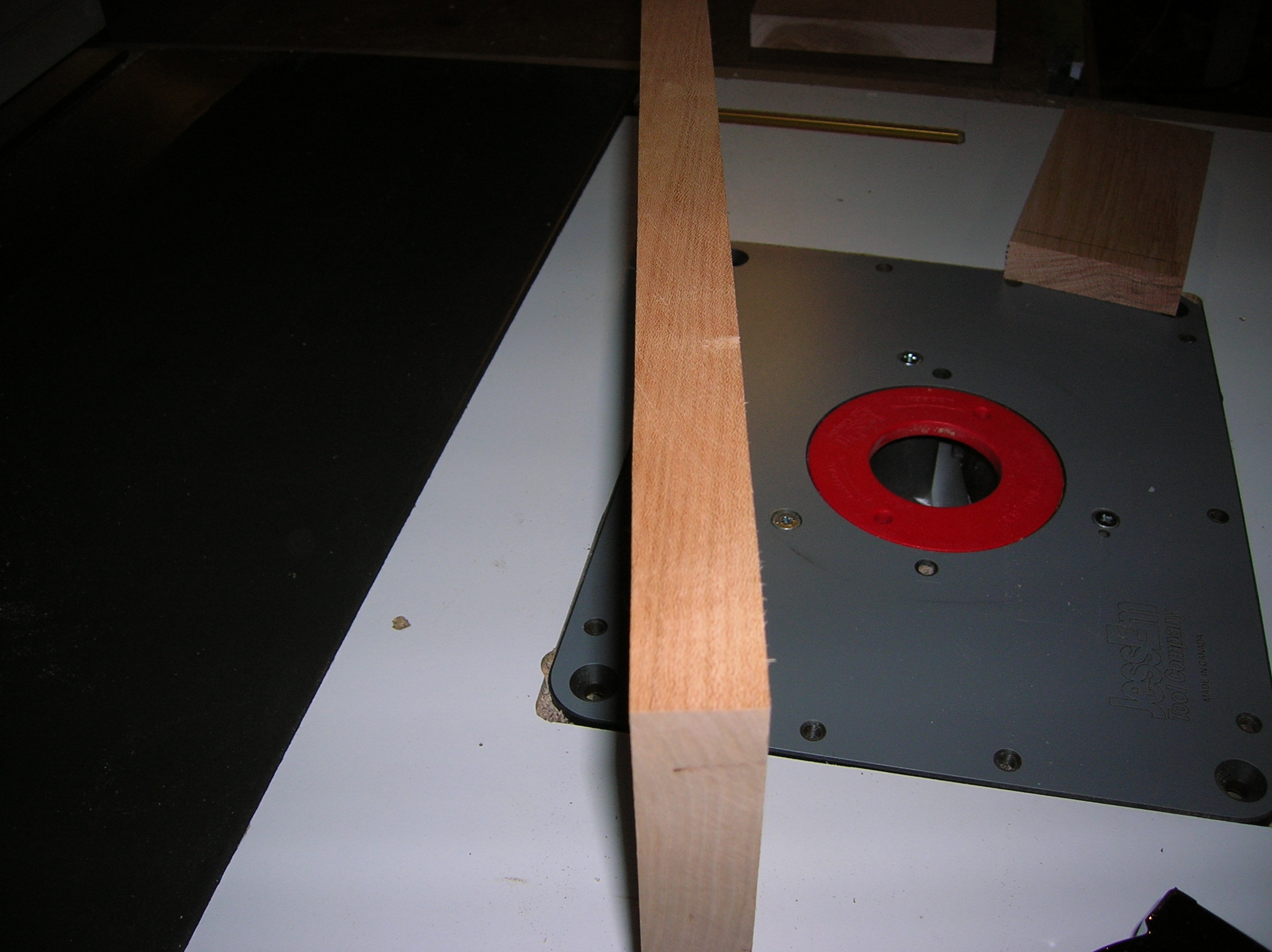

Next was hard maple. This offered more resistance than the cherry; however that was to be expected. The Diablo made the cuts quickly and efficiently. Again the cut was fairly smooth, but not glue-line:

Lastly, I ripped the Walnut. It was the easiest to cut effort-wise, but the ugliest finish. As you can see, this edge will need some work before any glue is spread.

Irwin

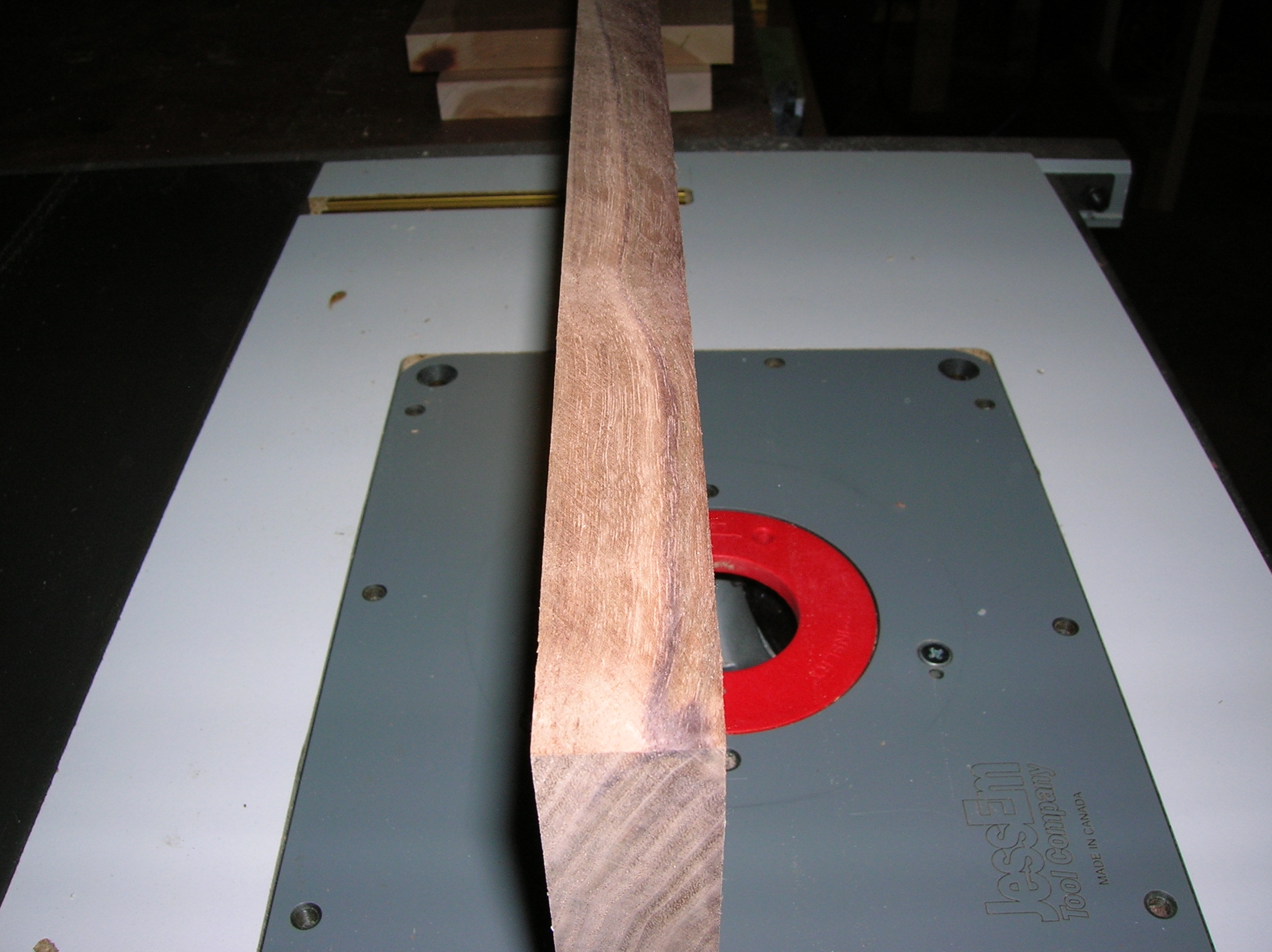

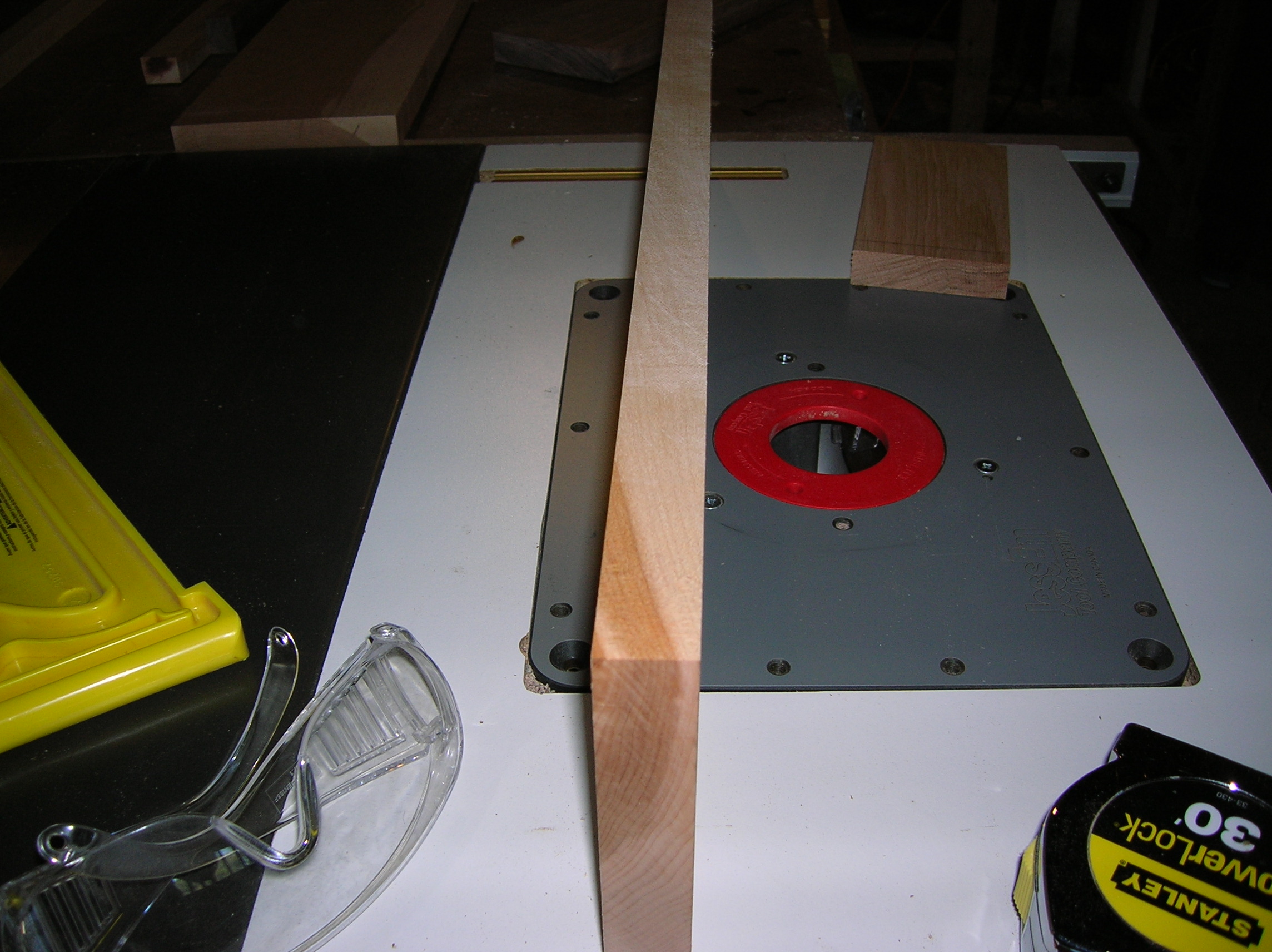

I changed blades and finished ripping my wood into strips. The first cut again was in cherry. The wood flew right through the blade, similar to the Diablo. No better or no worse. The cut quality however was much nicer. I would definitely spread some glue on this and get the clamps ready:

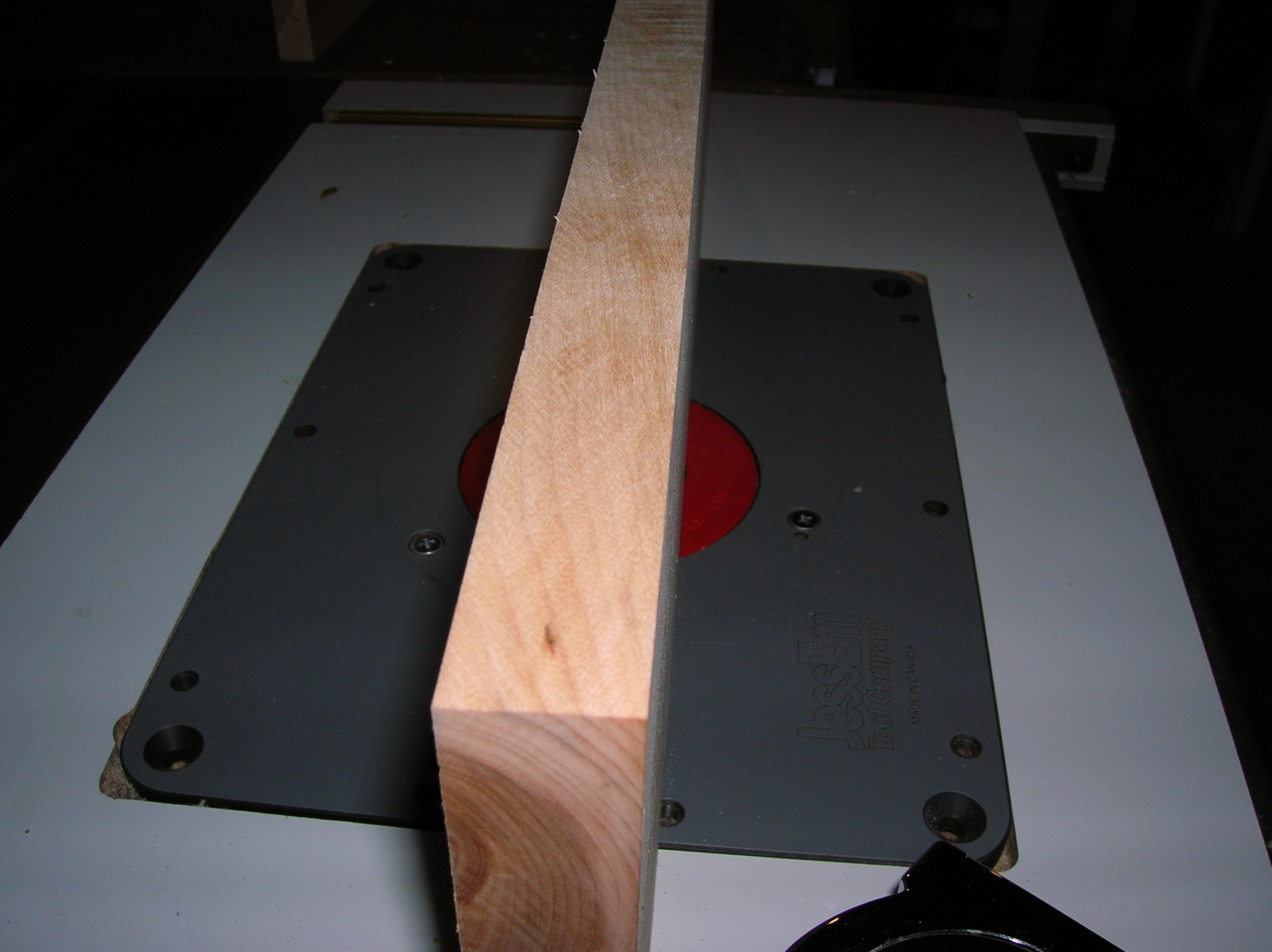

The next cut was into the hard maple. I was impressed here. As you can see by the pic I went right through a knot. I was expecting resistance or chatter but got none at all. No burning either. Again, the cut is pretty smooth and I would be comfortable going right to a glue-up as it is:

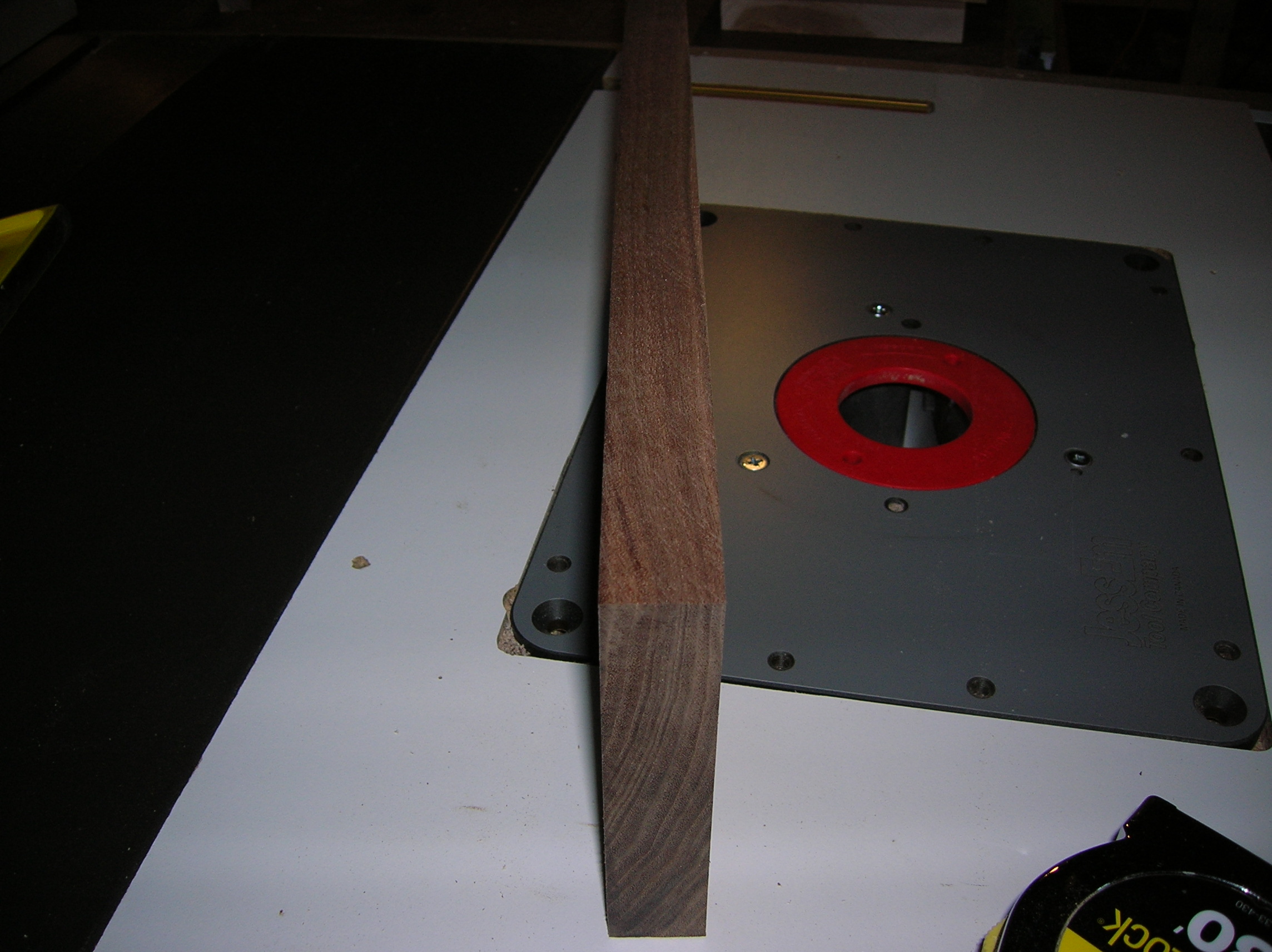

And finally that walnut that the Diablo sailed through but kind of chewed up? Not a problem here. Again ready for some glue and clamps:

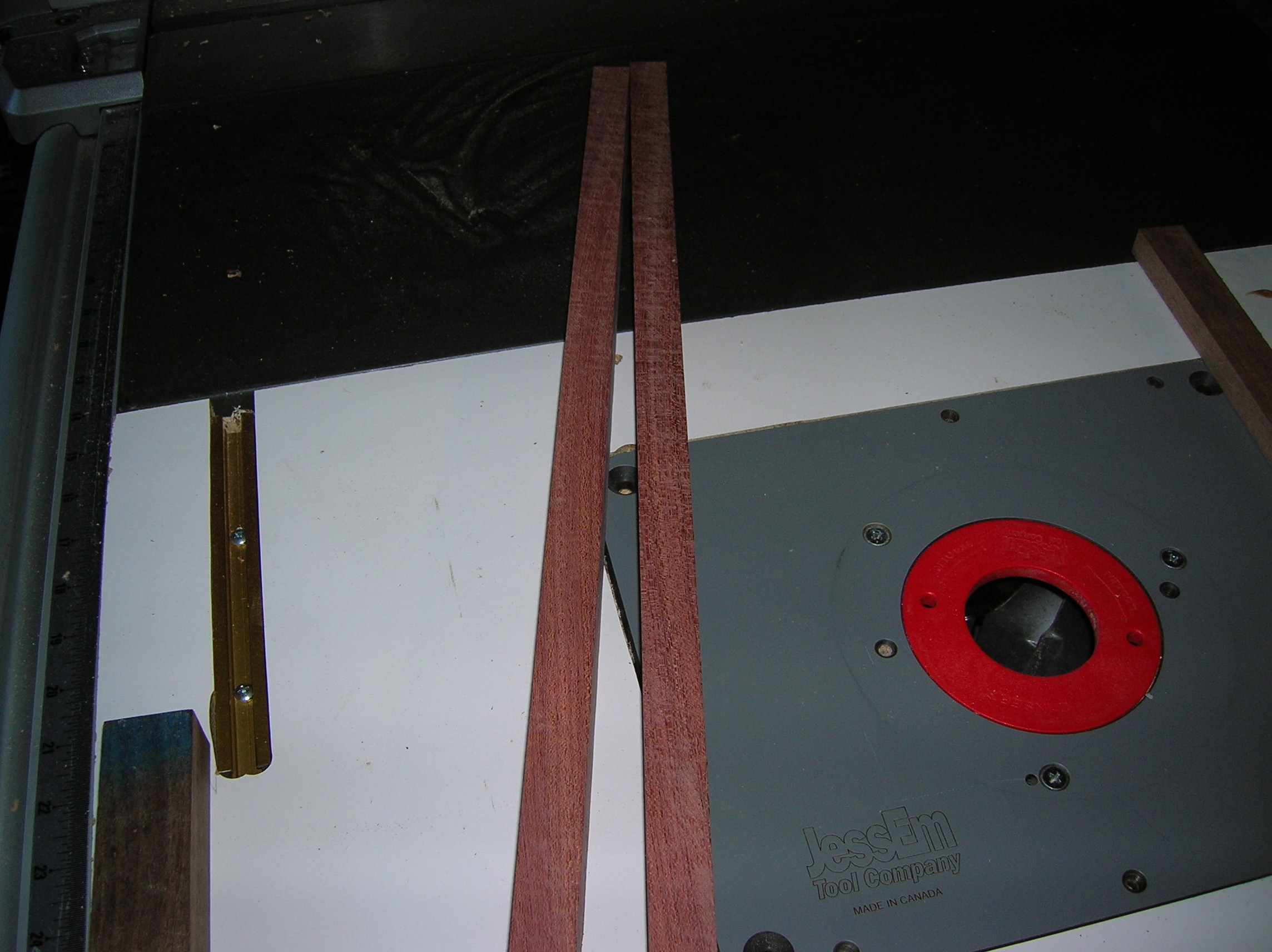

I even went on to rip some purpleheart. I was going to use a combo blade because purpleheart has a tendency to tear out and chip around the edges, but that was not the case here:

Summary and overall Observations:

Having a 24 tooth rip blade made my saw feel like it had an extra horsepower over a general purpose or combination blade. The trade-off is smoothness of cut. The Irwin did a fantastic job there. The cuts were effortless and while they weren’t mirror smooth, they were good enough for me to leave alone and glue away. I would not have done the same with the rip cuts made by the Diablo 24 tooth.

If you have an underpowered saw and need some mechanical advantage when breaking down thick or hard/dense stock, please go out and grab the Irwin Marples 24 tooth rip blade. The quality of cut and efficiency of cut is excellent. I will be using this blade a lot more than I thought I would. It is a very welcomed addition to my collection. Like with the 50 tooth combo blade I feel again that Irwin has bested the mighty tried and true bright red Diablo.

- Joseph laviolette